An article takes you into the world of plasma spheroidization technology

Regarding the plasma spheroidization technology, I believe many unfamiliar people will feel confused. First of all, we must understand what plasma is? Let's understand the principle and classification of plasma spheroidization technology. Now let's walk into the world of plasma spheroidization technology with the editor of SKYLINE.

Plasma state diagram

1. What is plasma?

When the ionization process occurs frequently and the concentration of electrons and cations reaches a certain value, the state of the substance will also undergo a fundamental change, and its properties will become completely different from that of the gas. In order to distinguish it from the three states of solid, liquid and gas, we call this state of matter the fourth state of matter, which is also called the plasma state. As the temperature continues to rise, the atoms that make up molecules in the gas separate and form independent atoms. For example, a nitrogen molecule will split into two nitrogen atoms. We call this process the dissociation of molecules in the gas. If the temperature is further increased, the electrons in the atoms will be stripped from the atoms and become positively charged nuclei and negatively charged electrons. This process is called ionization of atoms. When the ionization process occurs, plasma is formed.

2. Principle and classification of plasma spheroidization technology

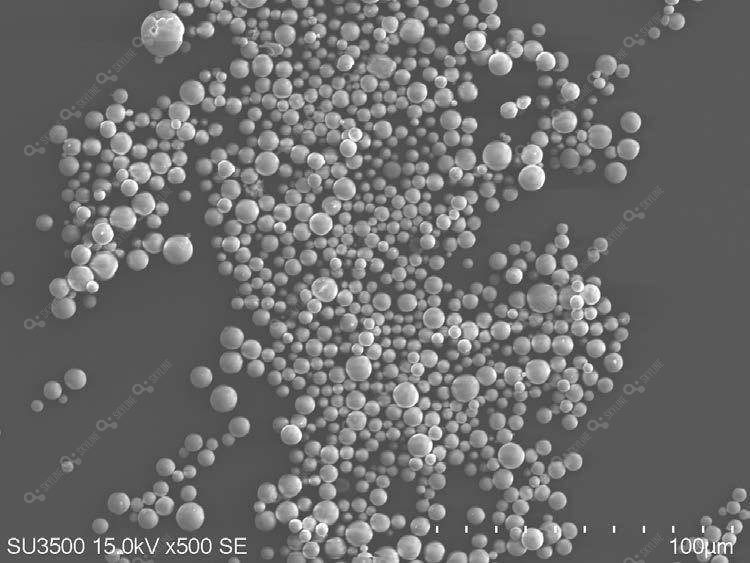

The principle of plasma spheroidization treatment technology is: using the high temperature environment of thermal plasma, the carrier gas sends the powder into the high temperature plasma, the powder particles quickly absorb heat and the surface (or the whole) melts, and polycondenses under the action of surface tension. After entering the cooling chamber, the liquid droplets are formed into spherical liquid droplets, and they are rapidly solidified to fix the spherical shape, thereby obtaining spherical powder.

According to the plasma excitation method, the plasma spheroidization treatment method can be divided into two categories: DC plasma and radio frequency plasma. The direct current plasma spheroidization treatment technology has the advantages of high energy conversion rate, high product output, low investment, and easy realization of large-scale industrial production; the radio frequency plasma spheroidization treatment technology is the Joule heating effect of the induced current under the strong electromagnetic coupling action. The air flow is heated to a very high temperature to form a self-sustainable plasma. The heating temperature range can reach 10000~30000K, and the quenching speed can reach 105K/S. It is a good way to prepare spherical powder with uniform composition, high sphericity and good fluidity.

Third, what are the strengths of Skyline in plasma spheroidization technology

Skyline has mastered the production capacity of two technologies of gas flame spheroidization and radio frequency plasma spheroidization and two production devices. Plasma spheroidization can reach the extreme high temperature of nearly ten thousand degrees, and it is easier to handle the melting point higher than alumina. Many ceramic materials such as magnesium oxide and zirconium oxide and tungsten, molybdenum, tantalum, niobium metals and their alloys, but the gas flame spheroidization equipment has outstanding advantages such as large production capacity and low production cost. It is used for industrial oxidation of irregular shapes. The spheroidizing treatment of aluminum and silicon oxide powder has great advantages.

On the basis of achieving micron-level spherical alumina and silica, Skyline continues to develop and solve the dispersion problem of sub-micron and nano-level spherical alumina materials during transportation, and develops a unique feature that is not suitable for centrifugal collection under microgravity. Some collection processes have realized the full coverage of the full range of thermally conductive fillers with spherical alumina ultra-wide particle size in the market.

Skyline has realized the mass preparation of nano spherical alumina, and is currently working on the mass preparation project of spherical magnesium oxide. Skyline, as a domestic high-end powder equipment supplier that launches large-scale spherical alumina production equipment, I believe it will rely on The development of this technology is getting better and better, let us look forward to it together!