Skyline:Introduction of metal powder production process

Powder metallurgy is the industry that manufactures metal powders and uses metal powders (including a small amount of non-metal powders) as raw materials, and uses the forming-sintering method to manufacture materials and products. With the development of modern powder metallurgy manufacturing technology, powder metallurgy products can replace conventional metal casting, forging, cutting, and mechanical parts with complex structures that are difficult to cut, and their supporting applications continue to expand. From general machinery manufacturing to precision instruments, from hardware tools to large-scale machinery, from electronics industry to motor manufacturing, from civil industry to military industry, from general technology to cutting-edge high technology, powder metallurgy can be seen. In the field of civil industry, powder metallurgy products have become indispensable basic components for industries such as automobiles, motorcycles, home appliances, power tools, agricultural machinery, and office appliances.

The huge potential of the market is also driving technological progress. As powder metallurgy products become more and more widely used, the requirements for the size, shape and performance of metal powder particles are getting higher and higher, and the performance and size and shape of metal powder depend to a large extent on the production method and preparation of the powder Technology, so the powder preparation technology is also constantly developing and innovating.

Shapes of metal powder produced by different methods

At present, many methods have been developed for the preparation of metal powders, which are mainly divided into physical and chemical methods and mechanical methods according to the production principle. The main methods in the mechanical method are the atomization method and the mechanical pulverization method.

The main methods in physical and chemical methods are reduction, electrolysis and hydroxyl method.

The characteristics and scope of application of metal powder preparation methods

1.Mechanical method

The mechanical method is a processing method that breaks the metal into powder with the required particle size by means of mechanical external force. The chemical composition of the material is basically unchanged during the preparation process. At present, the commonly used methods are atomization method and mechanical pulverization method. The advantages are simple process and large output, and can prepare some ultra-fine powders of high melting point metals and alloys that are difficult to obtain by conventional methods.

Mechanical pulverization

Mechanical pulverization is not only an independent powdering method, but also an indispensable supplementary process for other powdering methods. The solid metal is broken into powder mainly through crushing, crushing and grinding. There are two types of crushing equipment:

Coarse crushing equipment mainly used for crushing: crushers, roller mills, jaw crushers and other coarse crushing equipment;

The fine crushing equipment that mainly plays the role of crushing and grinding: hammer crusher, rod mill, ball mill, vibrating ball mill, stirring ball mill, etc.

Preparation of metal powder by high-energy ball milling

The mechanical crushing method is mainly suitable for crushing brittle and easy to work hardening metals and alloys, such as tin, manganese, chromium, high-carbon iron, ferroalloys, etc. This method has low efficiency and high energy consumption. It is mostly used as a supplement to other powdering methods or used to mix powders of different properties.

Atomization

The method of directly crushing liquid metal or alloy to obtain powder is called atomization method, which is the most widely used metal powder preparation method second only to reduction method in production scale. Atomized powder has the advantages of high sphericity, controllable powder particle size, low oxygen content, low production cost and adaptability to the production of various metal powders. It has become the main development direction of high-performance and special alloy powder preparation technology, but the production efficiency is low. , The yield of ultra-fine powder is not high, and the relatively large energy consumption limits the application of the atomization method.

2.Physical Chemistry Method

The physical-chemical method refers to the production method of obtaining ultra-fine powder by changing the chemical composition or aggregation state of the raw material in the powder preparation process. According to different chemical principles, it can be divided into reduction method, electrolysis method, carbonyl method and chemical replacement method.

Reduction method

Reduction of metal oxides and metal salts to produce metal powder is a widely used powdering method. Especially when ore and metallurgical industry wastes such as rolled steel scale are used directly as raw materials, the reduction method is more economical and practical. The advantages of the reduction method are simple operation, easy control of process parameters, high production efficiency, low cost, and suitability for industrial production. The disadvantage is that it is only suitable for metal materials that easily react with hydrogen and become brittle and breakable after hydrogen absorption.

Electrolysis

Electrolysis is a method in which metal powder is deposited on the cathode by electrolyzing molten salt or an aqueous salt solution. It occupies an important position in powder production. Its production scale is second only to reduction method in physical and chemical methods. It can control the particle size of the powder, and the purity of the prepared powder is high, and the elemental powder can reach more than 99.7%. However, the electrolysis method consumes more electricity, and the cost is higher than that of reduced powder and atomized powder. Therefore, in the total output of powder, the proportion of electrolytic powder is relatively small.

Carbonyl Method

Since metal carbonyl is easily decomposed into metal and CO gas at low temperature, the reverse reaction of synthesizing metal carbonyl can be used to prepare metal carbonyl powder. The carbonyl method can be used to prepare not only micron-level powders, but also nano-level powders; not only single pure metal and alloy powders can be prepared, but also coated powders can be prepared. The highly developed surface of carbonyl powder itself is incomparable to powders prepared by other methods, and it is a good material for chemical power supply plates and catalysts.

Chemical displacement

According to the activeness of the metal, the active metal is used to replace the less active metal from the metal salt solution, and the metal (metal powder) obtained by the replacement is further processed and refined into metal powder by other methods The method is called chemical replacement method. This method is mainly applied to the preparation of inactive metal powders such as Cu, Ag, Au and so on.

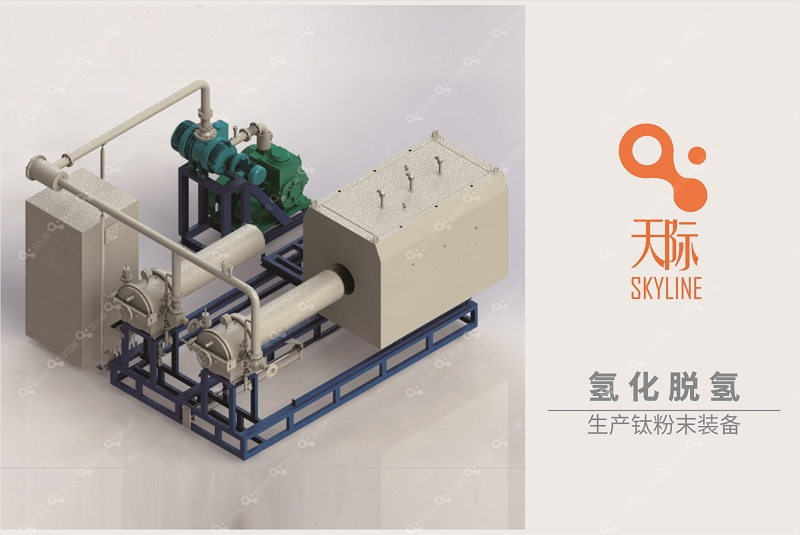

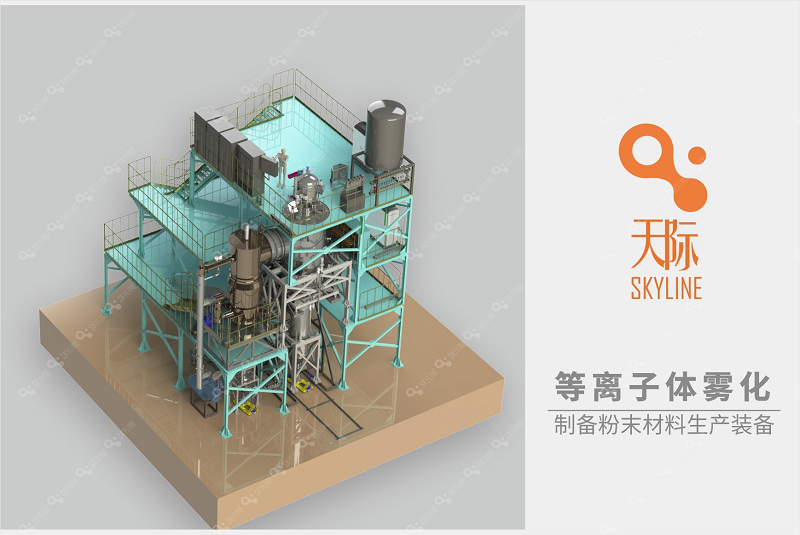

Hunan Skyline Smart Material Technology Co., Ltd. was established in 2018, (more than 20 years of industry experience), located in the Eastern Industrial Park of Yiyang High-tech Zone, Hunan Province, High-tech Zone, as a professional R&D and manufacturing of intelligent new material production technology and equipment, and providing comprehensive solutions for innovative material preparation A high-tech company, especially focusing on the research and development of various structural and functional ultra-fine, micro-nano powder new materials, and the manufacturing of production equipment. The product industry chain includes high-performance powder material preparation technology and equipment, powder material modification technology and equipment, powder rapid prototyping products sintering and heat treatment technology and equipment, etc. The industry technologies involved in chemistry, metallurgy, and materials science, Quantum mechanics, as well as mechanical design technology, thermal control technology, atmosphere control technology, vacuum control technology, intelligent control technology, Internet technology, etc. These intersecting sciences and technologies are integrated and integrated, which are comprehensive and professional, with a high degree of complexity. The company will continue to increase R&D investment, introduce innovative talents, develop several industry technologies and equipment with complete intellectual property rights, and apply for multiple patents; we will take professional technology as the guide, innovation-driven development, and integrate uniqueness and novelty. , Professional intelligent technology continuously upgrades our products and services, becoming the benchmark of product innovation in this industry, and making sparing efforts in innovation become our core competitiveness in the market.