- Home

-

Product

Advanced Po.. Powdered Ma.. Powdered Pr.. Advanced He..

- Solution

Powder addi.. High pressu.. Solutions o..- R & D

Test and sh.. Rotating Di.. Industrial .. Plasma Atom.. Gas atomiza.. Co-develope..- News

- About skyli..

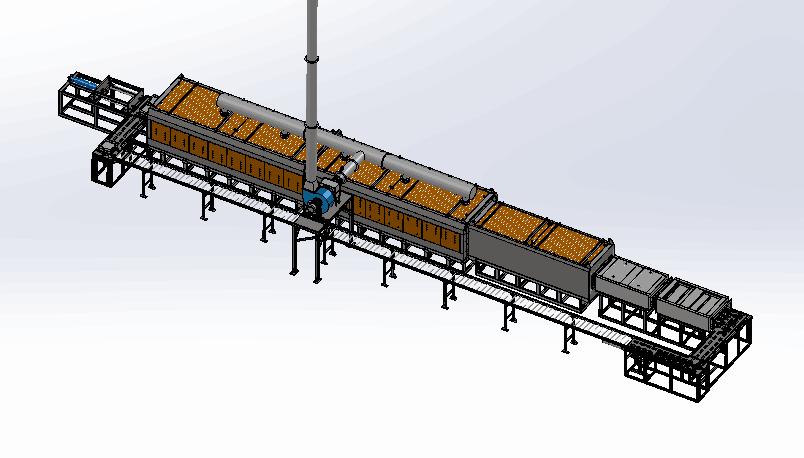

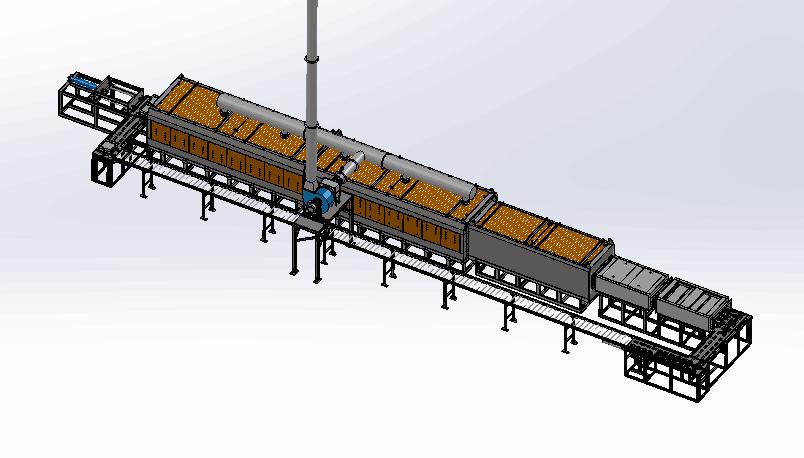

Pusher Calcination Equipment

Technical principle: Some salt materials are calcined at different heating temperatures to undergo decomposition or combination reactions to form oxides or multiphase materials; the loading saggers are arranged and pushed in heating equipment filled with hydrogen or other types of atmospheres to produce these powders ..

Immediately consultProduct introduction

Fully automatic push plate kiln calcining equipment is our company's development of push plate kiln for the production of high-quality battery materials in combination with years of technical experience in manufacturing sintering furnaces.The equipment is mainly composed of a fully automatic hydraulic propulsion system,a heating furnace body,an inlet and outlet system,a heating system,a gas system,a cooling system,an automatic circulation system,an electrical system,and an intelligent temperature control system.,Easy operation,high efficiency,energy saving,good temperature uniformity,stable and reliable product quality.

Picture diagram(this picture is for reference only,not for acceptance criteria)

Second,equipment structure characteristics

2.1.Separate operating systems are installed on the front and back of the device,which is easy to operate,debug and maintain;

2.2,with central control system;

2.3.Set over-temperature and current overload protection devices;

2.4.Sound and light alarms and records for all faults;

2.5 The equipment has automatic protection against leakage and short circuit;

2.6 The power supply of the meter can be switched to the backup power supply when the transmission system encounters a power failure;

III.Brief Description of Process

3.1.The product is calcined under the protection of air atmosphere;

3.2.The product is placed in a box bowl,and then the box bowl is placed on a push plate and pushed into the furnace by the propulsion system for calcination;

3.3.Product technology:room temperature to 650°C;heat preservation for about 5 hours,then enter the water cooling section to cool down to 100-150°C to discharge.

3.4.Atmosphere requirements:The entire process is an atmospheric environment.There are multiple air induction systems on the top of the furnace.The frequency of air induction is controlled by frequency conversion and the air pressure in the furnace is adjusted.There are multiple sets of air induction systems in the insulation and cooling section.Accelerate the material cooling speed,and at the same time can ensure the oxygen content in the furnace.The furnace body is open at both ends so that air can enter smoothly.

3.4.Burn-out rate of the product:about 20%.

Contact us

Tel:+86-0737-6685966

Email:export@skylinesmt.com

Address:Building H1, Standardized Factory, East New District, Hi-tech Zone, Yiyang City, Hunan Province

LINKEDIN:https://www.linkedin.com/in/zeng-hugo-611046195/ FACEBOOK:https://www.facebook.com/skyline.tech.88888 whatsapp/skype/wechat: +86 18163616773Online message

Copyright © 2019 Hunan Skyline Smart Material&Technology Co., Ltd. Recordcode:湘ICP备19004376号-1 Business license enquiry Map Technical support:jingwangzhiying

- Solution