- Home

-

Product

Advanced Po.. Powdered Ma.. Powdered Pr.. Advanced He..

- Solution

Powder addi.. High pressu.. Solutions o..- R & D

Test and sh.. Rotating Di.. Industrial .. Plasma Atom.. Gas atomiza.. Co-develope..- News

- About skyli..

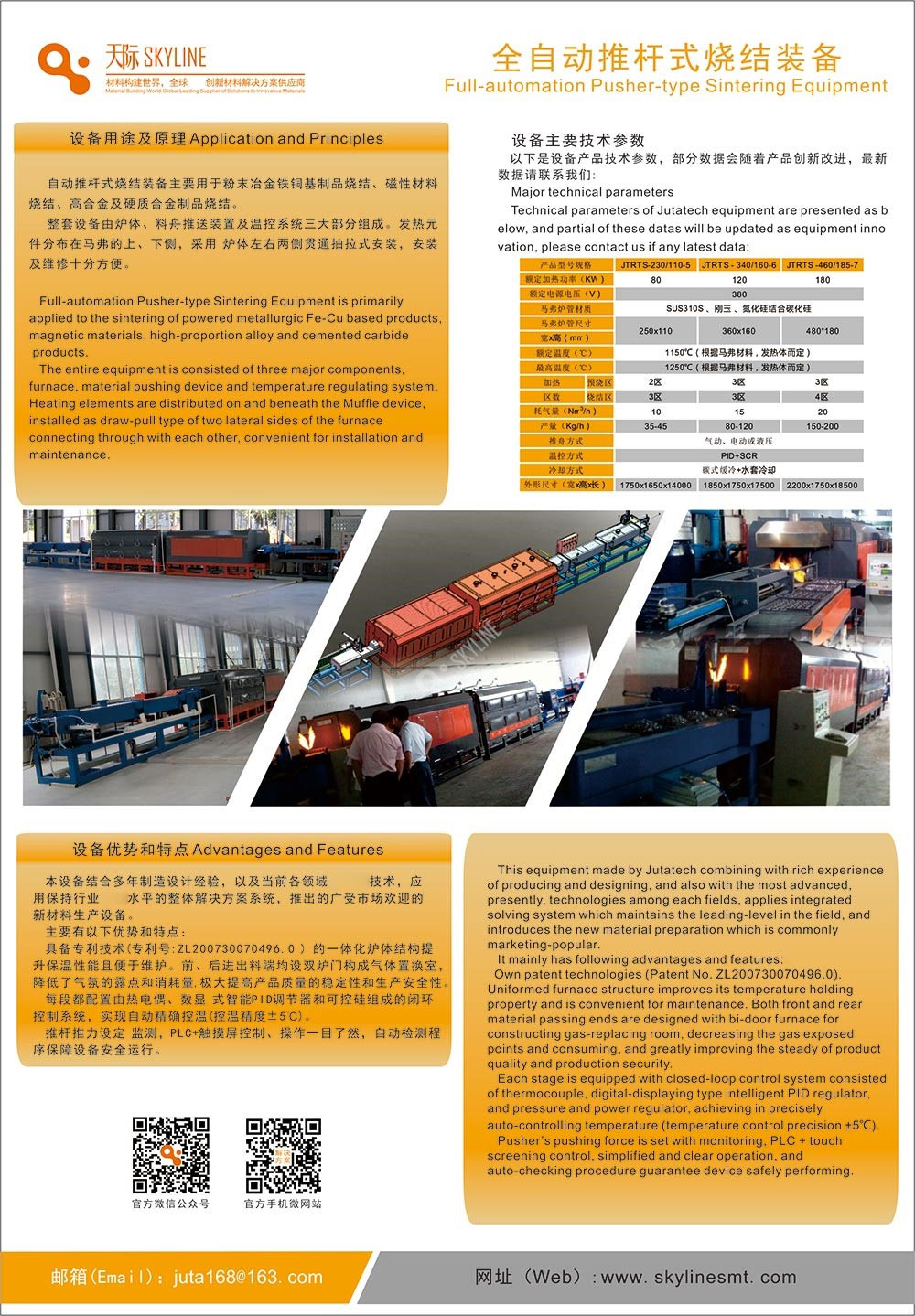

Full Automatic Pusher Sintering Equipment

Technical principle: The raw materials of the components produced by the compression molding and injection molding of the powder raw materials need to remove the binder added for easy molding, and then sinter and alloy at a certain heating temperature to obtain powder metallurgy components with excellent mechanical pr..

Immediately consultProduct introduction

Overview and Principles

Full-automation Pusher-type Sintering Equipment is primarily applied to the sintering of powered metallurgic Fe-Cu based products,magnetic materials,high-proportion alloy and cemented carbide products.

The entire equipment is consisted of three major components,furnace,material pushing device and temperature regulating system.Heating elements are distributed on and beneath the Muffle device,installed as draw-pull type of two lateral sides of the furnace connecting through with each other,convenient for installation and maintenance.

Advantages and Features

This equipment made by combining with rich experience of producing and designing,and also with the most advanced,presently,technologies among each fields,applies integrated solving system which maintains the leading-level in the field,and introduces the new material preparation which is commonly marketing-popular.

It mainly has following advantages and features:

Own patent technologies(Patent No.ZL200730070496.0).Uniformed furnace structure improves its temperature holding property and is convenient for maintenance.Both front and rear material passing ends are designed with bi-door furnace for constructing gas-replacing room,decreasing the gas exposed points and consuming,and greatly improving the steady of product quality and production security.

Each stage is equipped with closed-loop control system consisted of thermocouple,digital-displaying type intelligent PID regulator,and pressure and power regulator,achieving in precisely auto-controlling temperature(temperature control precision±5℃).

Pusher’s pushing force is set with monitoring,PLC+touch screening control,simplified and clear operation,and auto-checking procedure guarantee device safely performing.

Contact us

Tel:+86-0737-6685966

Email:export@skylinesmt.com

Address:Building H1, Standardized Factory, East New District, Hi-tech Zone, Yiyang City, Hunan Province

LINKEDIN:https://www.linkedin.com/in/zeng-hugo-611046195/ FACEBOOK:https://www.facebook.com/skyline.tech.88888 whatsapp/skype/wechat: +86 18163616773Online message

Copyright © 2019 Hunan Skyline Smart Material&Technology Co., Ltd. Recordcode:湘ICP备19004376号-1 Business license enquiry Map Technical support:jingwangzhiying

- Solution